PEM vs alkaline vs AEM: Why electrolyser technology choice matters

As global interest in hydrogen technology accelerates, the spotlight is turning to the technologies behind clean hydrogen production: electrolysers.

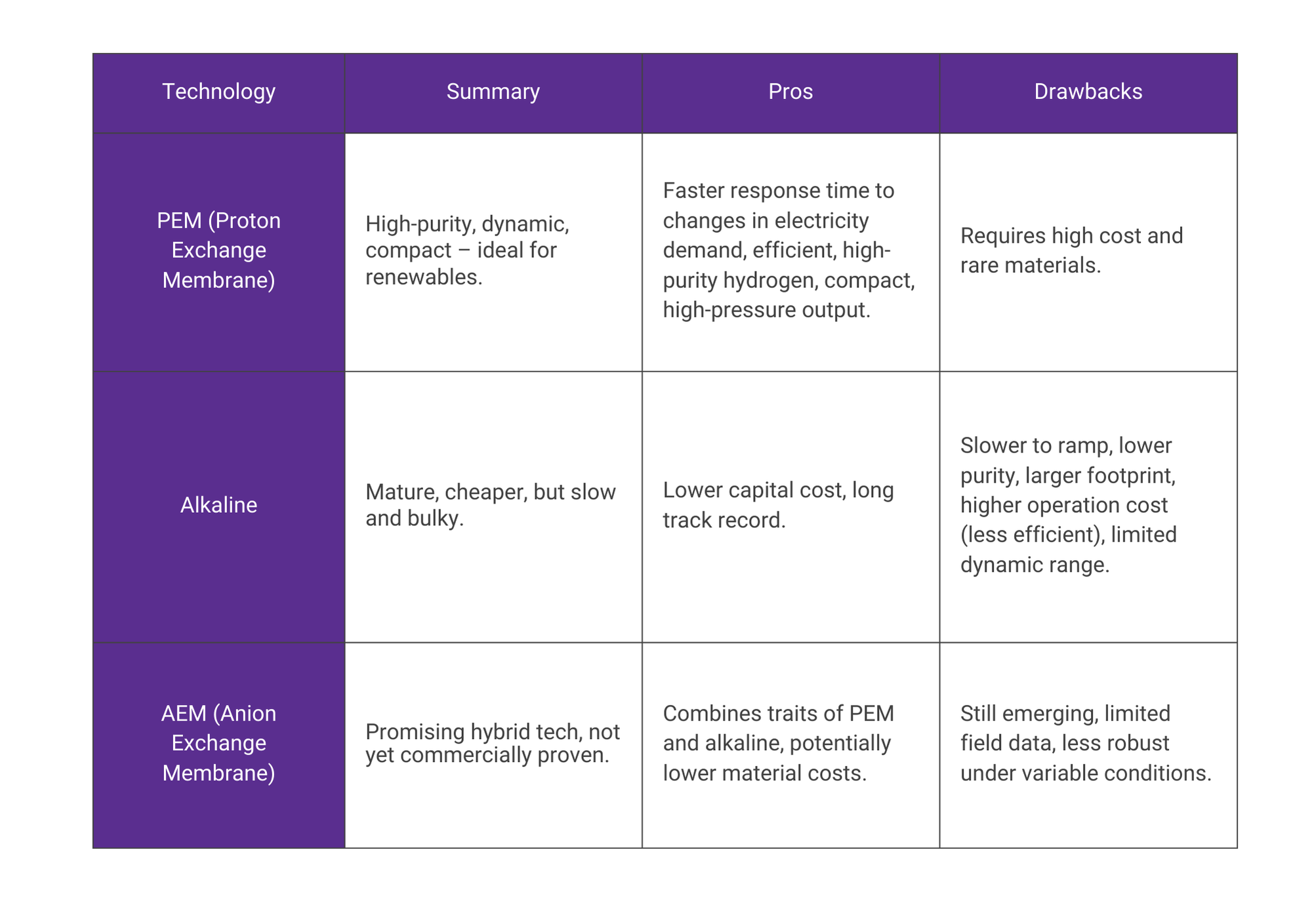

Considering there are several electrolyser technologies on the market (alkaline, PEM, and now AEM) it’s easy to get lost in the jargon. But the difference matters.

The right technology can impact the efficiency, purity and practicality of your hydrogen production, especially when working with renewables.

Let’s take a moment to cover how these options “stack” up.

PEM vs. alkaline vs. AEM

Why we use PEM technology (not alkaline)

Each electrolyser type brings its own set of trade-offs. At Endua, we use PEM electrolysis because it is better suited to dynamic renewable-powered green hydrogen production for use in fuel cells.

Built for variable renewables

Unlike alkaline systems, PEM can ramp up and down quickly to match the variability of renewable energy sources (solar and wind). This makes it ideal for real-time, on-demand hydrogen production using intermittent sources. Another often overlooked benefit, is how dynamic performance can assist to reduce system peak demand too.

More efficient

The electricity cost is typically the highest contributor to the cost of green hydrogen. PEM is more efficient in the production of hydrogen, and because it is more pure, less energy is consumed in post-production purification and compression. Less energy = a lower cost hydrogen.

Higher purity, higher pressure

PEM electrolysers produce hydrogen at greater purity and pressure, reducing the need for extra purification or compression before use or storage.

Smaller footprint, greater flexibility

PEM systems are more compact (~1/6th system size) than alkaline alternatives, making them easier to integrate into locations where space is limited – whether that is in off-grid, remote or urban environments.

Aligned with today’s energy needs

For flexible, clean hydrogen production that keeps pace with how energy is actually generated and consumed today, PEM simply performs better.

Cost efficiency

When it comes to long-term cost-efficiency, PEM also outperforms alkaline in real-world economics.

Over time, PEM technology demonstrates a lower total cost of energy than alkaline electrolysis. This cost comparison based on $AUD 0.20/kWh energy price, 40kg/day hydrogen production, and 30 bar delivery pressure.

What About AEM?

Anion Exchange Membrane (AEM) electrolysis is a newer, emerging technology that aims to combine the best of both alkaline and PEM systems, offering lower material costs with improved performance.

While AEM is promising, it’s still in the early stages of commercial development. It lacks the proven reliability and field data that PEM offers today, especially in dynamic, real-world environments.

At this stage, AEM remains a technology to watch, but it's not mature enough for real-world applications.

Final thoughts

As the world shifts toward renewables, hydrogen technology must evolve to match its pace and variability. PEM electrolysis stands out for its flexibility, efficiency and readiness to work in the real world, not just in controlled conditions.

Endua chooses PEM because it aligns with these requirements – producing hydrogen that’s clean, dependable and ready to support the way energy is generated today and into the future.

Hydrogen for the future starts with the right technology. Find out more about our PEM electrolyser technology and how it’s built for real-world renewable integration.