PEM electrolyser stack

The ES-50 is available as a standalone stack for system integrators, electrolyser OEMs, and engineering teams building bespoke hydrogen generation systems. High efficiency and pressurised output reduce system-level costs for integration into on-site hydrogen production installations.

High performance and purpose-built electrolyser stacks for direct system integration.

Endua remains agile and responsive to your technical requirements. Access to deployment expertise and an engineering team that understands real-world hydrogen systems means accelerated time-to-market.

30–100% turndown enables your system to track renewable energy output seamlessly - managing energy costs whilst maximising renewable asset utilisation.

Capture off-peak grid energy, integrate with solar and wind variability, and optimise around peak pricing periods.

50.6 kWh/kg stack efficiency delivers superior performance against conventional alkaline systems. Higher output pressure combined with PEM efficiency means better energy economics from a single integrated unit—critical at MW scale.

Industry-leading efficiency

Flexible load response for variable renewables

Compliant with regional standards & regulations

Higher pressure, lower compression cost

Modular stack architecture

Technology edge and technical partnership

Engineered to meet AS 22734:2020, AS/NZS 1200:2015, and relevant regional requirements. Endua works with you on compliance strategy—we understand deployment contexts across multiple jurisdictions and can support your certification pathway.

35 bar native output pressure significantly reduces compression requirements versus alkaline or low-pressure PEM stacks. Reduce compressor capital and operating costs by compressing less frequently at reduced energy.

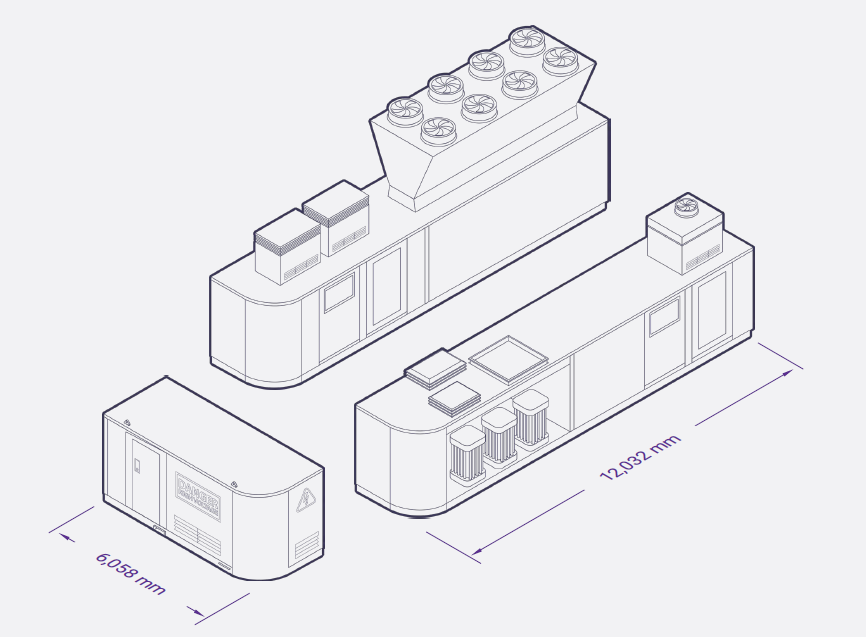

Standalone stack design gives you flexibility in system topology, allowing you to maintain design control. Scale from single-unit small systems to multi-stack configurations for larger capacity.

Why Endua

The ES-50 is built on years of CSIRO research and extensive testing and validation. We are a technology leader driving PEM electrolyser innovation. As an agile, focused company, we work flexibly with system integrators to support specific requirements. You will get access to cutting-edge hydrogen technology from a partner that understands the challenges of deploying across variable Asia Pacific markets.

Core performance metrics

ES-50 Electrolyser Stack Specifications

Frequently asked questions

Technical questions about the ES-50 stack

-

The ES-50 is a standalone electrolyser stack designed for integration into larger hydrogen generation systems. It includes the PEM membrane, electrodes, cooling circuit, and gas handling components. You'll integrate it with external power supply, water treatment, hydrogen purification, and control systems appropriate to your application.

-

35 bar delivery pressure is a sweet spot for cost-effective system integration. It eliminates the most expensive part of downstream compression (atmospheric to ~20 bar) whilst remaining manageable for standard industrial equipment. This reduces total system cost by 0.15–0.30 USD/kg compared to near-atmospheric alternatives.

-

Yes. The 30–100% turndown range enables efficient operation across variable load profiles. Current scales linearly with input power, making load control straightforward for OEMs and system integrators. This flexibility is particularly valuable for renewable energy integration.

-

The ES-50 accepts potable water per ASTM D1193 Type I. It tolerates modest conductivity variations typical of municipal supplies. For challenging water sources, you may need to add polishing stages to your water treatment circuit, but this is application-specific.

-

The ES-50 is intended for system integrators, OEMs, and engineering teams building bespoke hydrogen generation systems. You bring the complete system design, power supply, water treatment, purification, and control logic. Endua provides the proven electrolyser stack.