High performance electrolysers for direct industrial use of green hydrogen

Reliable hydrogen technology for energy and fuels

PEM electrolyser technology that makes on-site hydrogen production simple and commercial

Cost effective

Achieve large-scale plant efficiency without the massive infrastructure investment. Our compact systems eliminate hydrogen transport costs and bulk storage requirements, delivering green hydrogen directly where you need it.

Predictable supply

On-site green hydrogen production enables you to control your volume of supply, while providing absolute transparency of carbon and energy footprints.

Low effort

With autonomous operation and cloud-based monitoring, our PEM electrolysers deliver reliable on-site hydrogen production – while you focus on growing your business. Our plug-and-play design transforms installation from months to hours.

Many uses

Unlock more value from hydrogen across wide use cases – including chemicals, industrial heat, food production, steel, energy, fuels and mobility.

Ready to deploy hydrogen technology

Endua engineers and manufactures plug-and-play hydrogen technology solutions for gases, fuels, and energy storage – ready to accelerate your operations today

Electrolyser

Compact hydrogen production

250 kW

(4.7 kg/hr)

Industrial MW solutions

1 MW+

(18.8 kg/hr)

-

Liquid Hydrogen

Synthetic Gas

Industrial heat and boilers

e-Fuel feedstock

Mobility - Land, marine & aviation

Green Steel

Food preparation

Power bank

Power delivery

100 kW

(40 hrs cont.)

Multi-day or multi-week storage

3 MWh

(per container)

-

Remote Energy Systems

Microgrids

Mining

Agriculture

Environmentally sensitive locations

Water treatment

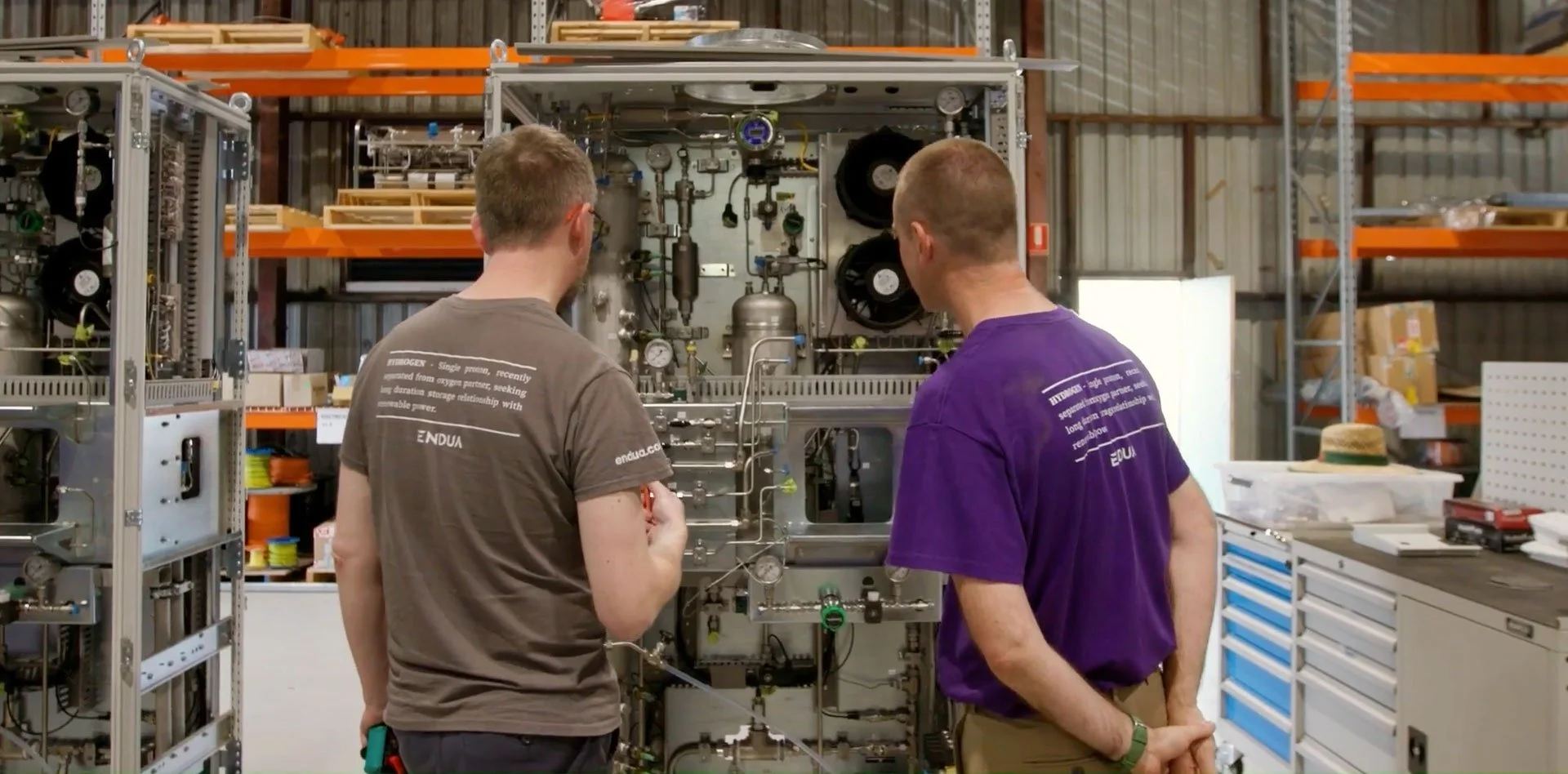

Innovation that stacks up

In collaboration with our science and technology partner, CSIRO, Endua has over 19 years of research and development effort into PEM electrolysis technology.

Our clean sheet electrolyser stack design optimises performance, materials and efficiency to achieve market leading outcomes in a smaller package

High performance

Our advanced stack design operates at higher current densities than conventional systems, delivering more hydrogen per dollar invested in equipment—giving you large-scale efficiency in a compact footprint.

High efficiency

High system efficiency produces hydrogen at a lower input cost and a wide dynamic operating window increases utilisation while managing grid energy costs

Renewable ready

With thousands of hours of benchmarking under constantly changing energy profiles, our technology performance holds up under the variable demands of renewable energy.

Validated by extensive operations and testing

-

Initial demonstration system

The demonstration system was first realised in June 2023. It was the first system of its kind to be approved under the hydrogen safety code of practice and has provided key information in the operation of hydrogen long duration storage applications

-

Archerfield Airport deployment

Endua successfully delivered this electrolyser system at Archerfield Airport in November 2024. The project validated the rapid deployment of our technology, reducing installation time down from months to hours. This installation provides key insight into the reliable remote operation of the electrolyser system.

-

Accelerated and long term testing

Proven reliability through the southern hemisphere's most extensive testing programme. Over 20,000 hours of rigorous testing validates our proprietary stack design—so you can deploy with confidence knowing the technology works

End-to-end project support

-

Technical and compliance support

Our technical and compliance support service reduces project risk by providing system integration planning, ensuring your hydrogen solution fits perfectly with your operational requirements and delivers optimal performance from day one.

-

Plant and equipment supply

Endua supplies complete hydrogen production plants and equipment, delivering proven technology systems that are pre-engineered, factory-tested, and ready for rapid deployment at your location.

-

Commissioning and testing

Endua provides comprehensive commissioning and testing services to ensure your hydrogen systems achieve specified performance from day one, with rigorous verification protocols and operational validation before handover.

Work with a global leader in PEM electrolysis

Learn more about how Endua’s PEM electrolysers and hydrogen technology can give you more control, flexibility and a faster pathway to adopting on-site hydrogen production. Or, get in touch with our team to see how we can support your energy strategy.